Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

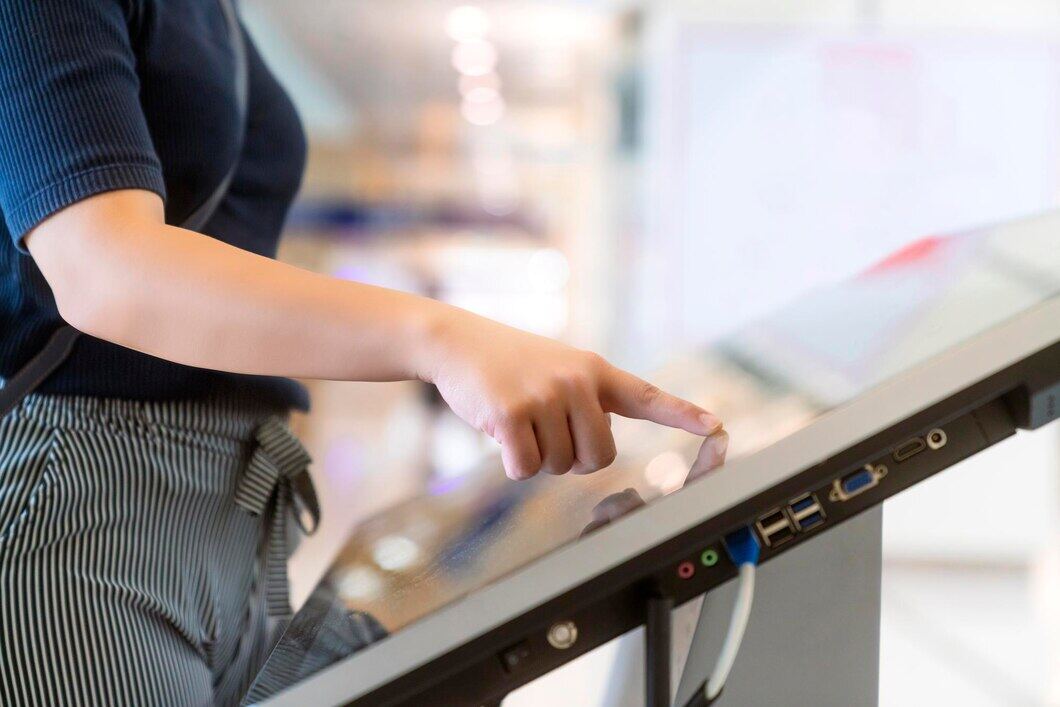

Touch screen displays have become an essential component of our daily lives in the modern digital age, completely transforming the way we engage with technology. Behind these sleek and intuitive interfaces lies a complex manufacturing process carried out in specialized touch screen display factories. This blog post delves into the evolution of these factories, highlighting their significance in enhancing user experience.

I. The Emergence of Touch Screen Technology:

Touch screen technology has come a long way since its inception. Initially, resistive touch screens dominated the market, consisting of two layers that required pressure to register touch. However, the introduction of capacitive touch screens, which respond to the electrical charge of a finger, marked a significant breakthrough in touch screen technology.

II. The Birth of Touch Screen Display Factories:

Early Manufacturing Processes:

In the early days, touch screen displays were manufactured using labor-intensive processes. These factories relied on manual assembly, involving the precise alignment of multiple layers, including the touch sensor, protective glass, and display panel. This method was time-consuming and prone to errors, resulting in lower production rates and higher costs.

Advancements in Manufacturing Techniques:

As demand for touch screen displays surged, manufacturers began adopting automated manufacturing techniques. This shift allowed for higher production volumes, improved accuracy, and reduced costs. Automated processes, such as optical bonding and laser cutting, enabled the seamless integration of touch sensors onto display panels, resulting in thinner and more responsive touch screens.

III. The Role of Robotics in Touch Screen Display Factories:

Precision and Efficiency:

Robotic automation has played a pivotal role in streamlining touch screen display manufacturing. Robots equipped with advanced vision systems can precisely position and align components, ensuring optimal touch sensitivity and display quality. This level of precision significantly reduces defects and enhances overall efficiency.

Flexibility and Adaptability:

Robots in touch screen display factories are designed to handle various screen sizes and formats, allowing for greater flexibility in production. With the ability to adapt to different product specifications, these robots enable manufacturers to meet the diverse demands of the market while maintaining high-quality standards.

IV. Advancements in Touch Screen Display Technology:

In-Display Fingerprint Sensors:

Recent advancements in touch screen display technology have led to the integration of in-display fingerprint sensors. This innovation eliminates the need for a separate fingerprint scanner, enhancing the aesthetics and functionality of smartphones and other devices.

Foldable Displays:

Touch screen display factories are now exploring the production of foldable displays, enabling devices with flexible screens. This breakthrough technology offers users a unique and immersive experience, expanding the possibilities of touch screen applications.

V. Future Prospects and Challenges:

Increased Demand:

With the growing popularity of touch screen devices, touch screen display factories face the challenge of meeting the increasing demand for high-quality displays. Manufacturers must continually invest in research and development to stay ahead of the competition and cater to evolving user expectations.

Sustainability and Environmental Impact:

As touch screen display factories continue to expand, it is crucial to address the environmental impact of manufacturing processes. Implementing sustainable practices, such as reducing energy consumption and minimizing waste, will be essential to ensure a greener future for touch screen technology.

Conclusion:

Touch screen display factories have played a pivotal role in transforming the way we interact with technology. From manual assembly to automated processes and the integration of advanced robotics, these factories have revolutionized the manufacturing of touch screen displays. As technology continues to evolve, touch screen display factories must adapt to meet the increasing demand for innovative and sustainable solutions, ensuring a seamless user experience for years to come.