Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

In the ever-evolving world of electronics, the COB (Chip On Board) LCD module stands out as a versatile and reliable component for a myriad of applications. Whether you're a hobbyist, a student, or a professional engineer, integrating an LCD module into your projects can significantly enhance user interaction and provide a visual interface for your devices. In this comprehensive guide, we will explore what a COB LCD module is, its advantages, applications, and how to get started with one in your next project.

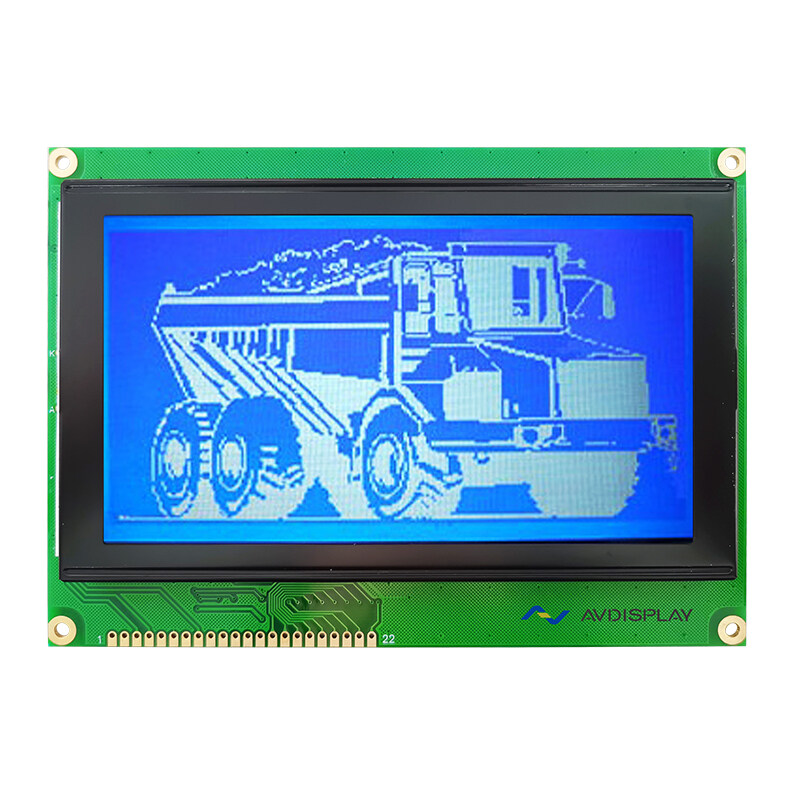

A COB LCD module is a type of liquid crystal display that is manufactured by directly mounting the IC chip onto the glass substrate of the LCD panel. This method of assembly is different from the more traditional method where the IC chip is mounted on a separate flex cable that is then connected to the LCD panel. The COB technology offers several benefits over the traditional method, including improved durability, reduced manufacturing costs, and a more compact design.

Enhanced Durability: The absence of a flex cable makes COB LCD modules more resistant to mechanical stress, which is particularly beneficial in applications where the display might be subjected to frequent movement or vibration.

Cost-Effectiveness: The simplified manufacturing process of COB LCD modules can lead to lower production costs, making them an attractive option for mass-produced devices.

Compact Design: The direct mounting of the IC chip onto the LCD panel allows for a more compact design, which is ideal for space-constrained applications.

Improved Reliability: With fewer points of failure due to the lack of a flex cable, COB LCD modules can offer higher reliability over time.

Customizable Options: COB LCD modules can be tailored to specific requirements, including size, resolution, and interface type, providing flexibility for various project needs.

Home Appliances: COB LCD modules are commonly used in home appliances such as microwaves, washing machines, and refrigerators, where a user-friendly interface is essential.

Industrial Equipment: In industrial settings, COB LCD modules provide clear displays for monitoring equipment status, process parameters, and alerts.

Medical Devices: The reliability and durability of COB LCD modules make them suitable for medical devices where accurate and stable displays are critical.

Automotive Systems: In automotive applications, COB LCD modules can be found in dashboard displays, navigation systems, and rear-seat entertainment systems.

Portable Electronics: Due to their compact size and low power consumption, COB LCD modules are ideal for portable devices like digital cameras, GPS units, and handheld gaming consoles.

Choosing the Right Module: The first step is to select a COB LCD module that matches your project requirements. Consider factors such as display size, resolution, color depth, and interface (parallel, serial, or I2C).

Understanding the Pinouts: Familiarize yourself with the pinout diagram of the COB LCD module. This will help you understand the connections for power, ground, data, and control lines.

Gathering Necessary Components: Along with the COB LCD module, you will need a compatible microcontroller or processor, a power supply, and possibly additional components like a potentiometer for contrast adjustment.

Writing the Code: Most COB LCD modules come with libraries that simplify the process of sending data to the display. If you're using a popular microcontroller like an Arduino, you can find numerous libraries and examples online to get you started.

Assembling the Circuit: Connect the COB LCD module to your microcontroller following the pinout diagram. Ensure that all connections are secure and that the power supply is appropriate for the module.

Testing the Display: Upload a test program to your microcontroller to ensure that the COB LCD module is functioning correctly. This is a good opportunity to check for any issues with the connections or the code.

Incorporating into Your Project: Once you have confirmed that the COB LCD module is working as expected, you can integrate it into your project. This may involve writing custom code to display specific information or interacting with user inputs.

No Display: Check the power connections and ensure that the voltage matches the module's requirements. Verify that the contrast potentiometer is set correctly.

Garbled Text: This could be due to incorrect data being sent to the display. Double-check your code and ensure that you are using the correct library functions.

Slow Response: If the display is responding slowly, it could be due to a poor connection or an overloaded microcontroller. Check your wiring and consider optimizing your code.

Flickering Display: This might be caused by an unstable power supply or a loose connection. Ensure that all connections are secure and that the power supply is stable.

COB LCD modules offer a reliable and cost-effective solution for adding a visual interface to your electronic projects. Their durability, compact design, and customizable options make them a popular choice across various industries. By understanding the advantages, applications, and the process of getting started with a COB LCD module, you can enhance your projects and create more interactive and user-friendly devices.